Burnering,

or: Saga about burners. Part 1.

Since certain time our vocabulary has been enhanced by new meanings from several areas of social life (petting, pekhting etc.). In order not to be outside the actual trend and progressive community, I called my opus “Burnering, or: Saga of burners (homemade)”. Since early times I have really warm (sometimes hot) relationship to burners. Therefore I provide the present information having special feelings. It should be stated right from beginning that there will be information about gas, propane burners. I man namely injection burners, because the oxidizer (air) will be injected due to stream of burning gas (please don`t muddle up with fulminating gas), which goes outside of burner. But sometimes flow of air is not sufficient. In this case, in order to increase the burning temperature, air is pumped by blower. But anyway, there shouldn`t air from gas cylinder used, but atmospheric air.

That`s why the above mentioned burner is connected with one pipe only, namely

the one which goes from propane gas cylinder. In order to select the appropriate

burner which complies with your need, it is not sufficient to show the picture

and write some sentences only. Therefore I had to record some videos. It gives

more visualization.

Description of each burner will be accompanied by providing of drawings.

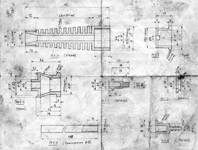

Mini burner

This burner was developed for soldering of filigree with very small parts, therefore the reduction of flame diameter was the focus. To the time when this burner was developed, there were no small burners with gas cylinder in shape of burner`s handle. That`s why the middle-sized burner (described further) was selected as the base for current burner; all the dimensions were appropriate reduced.

Soldering of small parts. Sometimes

there is lack of free hands while putting the solder and keeping the

parts of filigree :)

The present burner is special one, due to applying of dissector. It keeps

the stability of flame in whole area of pressure (within reasonable limits,

certainly), it means from 0.2 up to 3 kg/cm2. Volume of air will not be

controlled. This volume is limited due to diameters of holes of pump. If

there is needed to control the blow power, there is needed to put the piece

of silicon pipe into ring with knurl. Control is available by rotating of

ring. The selected diameter of nozzle is about 0,12 mm.

The one of approach how to build the

nozzle is shown. Capillary is soldered to screw, which is screwed into

the pipe. Screw is sealed by Teflon tape. Accuracy of axles should be

kept. It is possible to make the nozzle without capillary, in this case

the screw M3 should be drilled on bench.

Position of pipe with nozzle really should be regulated. After ignition of burner, the pipe should be moved back-forward, then the selected position should be fixed by screw.

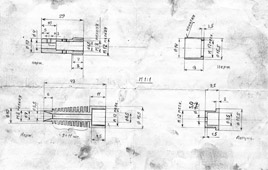

Middle-sized manual burner

This type of burner is the most universal for soldering of small and

middle sized jewelry parts by using of hard solders. (This method is

applicable if there is no need that both of hands are free :). Burning

stream can be controlled by using the same hand which keeps the burner. This

burner contains dissector as well, it means the flame will not go out under

either normal pressure of propane.

Control of flame by using the same hand. Area

of burner which should be used for hanging it on hook is protected by

silicon pipe. Material of the handle is ebonite.

Around the burner`s head area, the thermo-insulating coupling is fixed. Application of this coupling allows us to pre-warm the head area, which results in increasing of flame temperature. The material of coupling is asbestos cloth, with addition of kaolin and liquid glass. The part which should be soldered has to be located in recreation area of flame. The correctness of location can be checked: Put in flame a piece of cooper wire. The surface of metal becomes brilliant if it is correct put in flame`s recreation area.

Nozzles on this burner are done in the same way like on previous one. The aligned diameter of nozzle`s holes is 0.16 mm. Volume of air can be controlled if you put a piece of silicon pipe (with appropriate diameter) inside of ring. But if you use the dimensions as specified in my drawing, the mixture is normally balanced.

Middle sized direct burner

As you see I haven`t created any attractive names for burners, main criteria for me was - the names should be different. And each item has to be named. The next burner differs from the previous due to its geometry of location of its components, but the functionality concept is the same.

This burner has more soft flame, that`s why it should be used for preliminary warm up of some parts (surface burning of wires, patina application). Due to its dimensions, this burner can be used in case if there is no place enough to operate with the previously mentioned burner type (middle-sized manual burner). This burner contains dissector as well, similar to above mentioned burners. The additional air-feeding device is developed in unique form

There is no drawing available, because the main parameters are identical to the previously described burner. Head-coupling, dissector and diameter of the air feeding pipe are the same. And, which is more important, diameter of nozzle is also the same

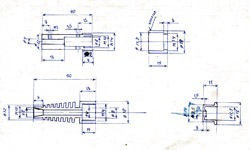

Large manual burner

This burner is similar to above mentioned burners. All parameters are the same, it differs due to its enhanced power only. This burner can be applied both for soldering of filigree and cooper pipes of fridge.

The one standard component of this burner is gas valve. It is not I-shaped (like in previously described models), but L-shaped. This valve is the base for fixation of all other parts of burner. The aligned diameter of nozzle`s hole is 0.23 mm.