Burnering,

or: Saga about burners. Part 2

Description of models of burner resulted in more volume than initially assumed. That`s why I divided scope of information in two parts. Part 1 contains information about non-large manual burners, applied mostly for soldering and warming up. Part 2 deals with large stationary burners. These burners are mostly installed in anneal muffle and melting ovens. Normally these burners are not adjusted to be handled manually. But why not? Further I will tell more about serial manufactured burners, than I will show their advantages and disadvantages as well as their specific of operation. These burners can be very large-sized, although they can be designed as to be manually operated.

Direct stationary burners of 1/2`` and 3/4``

This burner of stationary specification and can`t work without oven. If you work

without oven, flame will possibly go out (blowing it away if the compression

more than certain value, followed by replacement of burning process – deep

inside, up to nozzle, if the pressure is lower than certain values. It can be

explained by the case, that there is no flame dissector in the construction. The

dissector gives stability of the work. Instead of stationary burner there is a

trumpet foreseen. It is possible not to use the trumpet, but to use the direct

pipe.

But you have to insert the pipe or pipe socket in oven`s mouth. This results in

more stable burning.

Burner and oven in operation. Diameter of oven`s mouth should be

1,2-2 times more than diameter of burner`s pipe. If the diameters are

equal, the distance between the edge of pipe socket and diameter of

oven`s mouth should be about 1 cm.

But anyway, in first line it is required to define the position of burner

where the optimal torch-shaped burning occurs. Only after that, you can think

over about fixation tools.

All the burning components are made using the standard components. It means you

will pay not so much many as well. I have an inox pipe, you can use standard

pipes. The joint area is made of cast iron. Plugs are standard.Control of air amount is done due to the following approach.

Just turn the plug which is enrolled as a flap.

It is needed to tell that to set this burner on fire is more convenient if you will use another approach than I described before – relating to manual burners. In first line we should enrich the compound by meaning of turning of plug until the open-end holes are closed by plug. Than you should set it on fire. After that you start to open the plug little by little. It is well shown on video. After that the plug can be removed. The aligned diameter of nozzle`s hole is about 0.5 mm

This burner of size ¾`` is identical to previous one. There are different in size

and therefore in capacity. The aligned diameter of nozzle`s hole is about

0.8 mm.

The capacity of burner depends on amount of gas coming from nozzle. And

this amount corresponds with nozzle`s diameter and gas pressure. Geometry of

burner has influence on effectiveness of gas burning only.

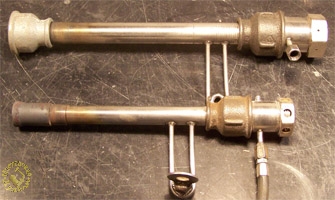

Direct burners 1/2" and 3/4" assembled. I changed my mind and I

will not drill the plug of large burner. I plan to correspond it to

blower.

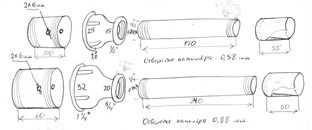

Production of nozzle (of those two types of burner) is different compared to burners described in Part 1. The covered on one end pipe should be installed across of large pipe and be slightly welded. Please drill a hole on the bench after that only! Due to this approach you achieve the coaxiality of holes of nozzle and pipe.

Angular stationary burners of sizes ½`` and ¾``

Compared with previously described burners, in present burners there are

some changes implemented. The reason is determined by application area of

those burners - large muffle oven heated by gas. In first, it means

reduction of oven`s overall dimensions due to pipe`s bended area with angle

of 90 degrees. In second, dissector of flame is used, which results in more

stable work of burner. This is important namely for large muffle oven

because the explosion in this oven could have unacceptable consequences.

Angular stationary burner located on oven. Gap is located in

oven`s opening area! It helps to set it on fire more easy.

Parts are mostly the same, made from standard semi-finished parts. But there are parts which need to be prepared on turning lathe, e.g. dissectors and nozzles. Main recommended material for nozzle is inox steel, but you can make it from common carbon steel. In this case, life time of this part is not sufficient.

Nozzle here is different to previously described lines. Acc.to drawing,

brass-made part will be prepared on lathe, it is necessary not to drill

holes, but make base for holes (not-drilled to the end of second surface)

using thick drill. After that you should drill through out hole using the

drill of corresponding diameter. Angular stationary burner of size ¾``.

On this video you can

see rather stable work while there was used a variety of gas pressure.

Ready-built burners

Hereby please a review of several ready-built burners. Idea of all the items described here was initiated several years ago, when there was a difficult situation in our country: there was a lack of products on market. Nowadays we have a lot of products in supermarkets, but quality depends and has impact on price. And stationary burners which I`m presenting now, maybe will remain as a home-maid product. Burners from lower price category DONMET. They contain four different changeable heads with nozzles. There is gas feeding valve installed on handles of burner. Bedside of this, control flame is showing that the lever has been released; when the lever has been switched on, gas feeding system starts to work, in amount acc.to control switch.

Sure, beside of above mentioned advantages, there are

some disadvantages. Material of caps is under corrosion. Those sipes are

nothing more than holes for additional air pumping. Due to their bad

shape, flame becomes one-sided, which – accompanied by absence of

dissector – results in often deflation of flame.

Burner DONMET in operation. All four caps have been checked in

successively way, beginning from the small one.

Now I`d like to demonstrate the work of such device as burner-nozzle which should be fixed on gas cylinder. Burner-nozzle. Air blowing is better than in case previously described, but the general quality of device resulted in one-sided blowing effect. I purchased this device in order to warm up the frozen in garage :o)