Homemade vacuumator (small one)

Vacuumator (vacuum chamber) works together with vacuum pump as mentioned below. Control of vacuum pump should be made from pedal with end sensor.

This vacuum pump is able to vacuumize the semifinished product and silicon compounds (not thick) of type Pentelast-710, Lacil and Lepta 101.

If you would like to form Vixint of type U1-1-18 or Pentelast-720, you should take one of these

http://becool.ru/service-tools/vacuum-pumps

The simple 1-step vacuum pump of type BS-VP-114 is quite enough.

Because to be correct in wording - we don`t make vacuum, but certain level of underpressure in chamber which is enough for our purposes.

Let`s clarify the terms, because related to this item, there are no any standards. Some vacuum manometers have scale 0 to 1, having start position on 1.

It means, vacuum occurs by 0. Other manometers have scale -1 to 0, having start position on 0. The case can be complicated

due to the fact that not all manometers have scale in kgf/cm2. Very often there is MPa

(or: bar) scale, some foreign have PSI as unit. Don`t brake heads about it,

let`s just confirm scale as follows.

Vacuum manometer DM15-63-1-M-(-1-0) kgf/cm2 -2,5

where

63 is diameter

1 standard model

M thread metrical, M12x1,5

(-1-0) scale kgf/cm2 measurement unit

2,5 precision class

In start position (by atmosphere pressure) arrow is positioned on 0. In vacuum the arrow will stay on -1 kgf/cm2.

While variations of atmosphere pressure, the pressure in closed chamber will also change, but we can ignore it.

Well, pressure 0,4-0,6 kgf/cm2 is enough for vacuumizing of form-mass, as for vacuumizing of silicons pressure till -0,9 kgf/cm2 is enough (depends on its thickness).

Actually manometer has supplementary function in this device. You can see the vacuumizing process by your own eyes through transparent cover.

You can make cover not such complicated like I did. Round or square piece of plexiglass or common glass. Main issue is, it should be of enough thickness.

Plexiglass is more preferable because after break it doesnt cause such amount of sharp fragments. For example, I have plexiglass of thickness 40 mm.

Even short calculation can show that pressure affecting the cover will be up to 250 kg, that`s why you should pay very serious attention to select of material for cover.

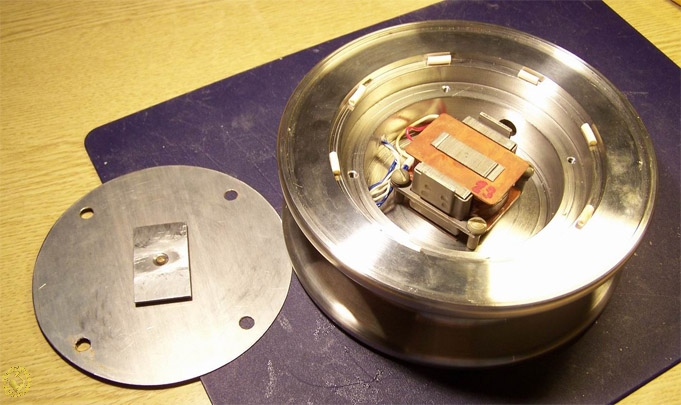

It is not necessary to make a hole for rubber sealing, but a hole made in pipe`s flange is necessary. Vacuumizer`s chamber is made of pipe`s piece.

There are flanges welded to this piece of pipe. Pipe is D=159/147x160 mm. After turning dimensions will be D=157/152x160mm. Lower flange has groove for rubber strip.

It is fixed to the base by using of car-sealant. It is so designed in order to assure easy access for dismantling of vibrator.

And chamber works for creation of underpressure and there is not needed to fix it strongly.

Base of unit should be solid enough, in order to ensure vibration of tank with its content, not vibration of everything around. Electro-magnet vibrator will be fixed by 4 screws to the base.

Base with electromagnet vibrator and membrane.

This is common transformer with open (from one side) magnet system, assembled from ุ-shaped transformer iron.

Such vibrator can be made by yourself, from the suitable transformer. In first, you have to disassembly transformer, having removed coil.

Then you should build iron back, but you have to segregate ุ-shaped parts and bridges and to put them separately.

It`s useful to operate with transformer iron, with holes the edges. So it`s better to fix.

Then we put ุ-shaped parts in coil and fix it together as strong as possible. You can even flood it by compound.

Bridges should be collected as well, you should fix them to membrane (which actually is supposed to be vibrated).

You can use strip of magnet-soft steel (like I did) and fix it by rivets with washer to membrane.

As working winding of vibrator you can leave the first winding of outcome transformer, having sequentially secondary windings added.

But it`s better to wind it by thin wire until the gap is filled.

In first version of device, membrane was fixed on studs (which are going through it) and hanged on springs.

But after touch f metal parts there was non-comfortable noise. That`s why I hanged the construction on pieces of silicon pipes.

As you see, vibrations of material happen in vertical plane, small dimensions allow us to do it.

Then I will download for you description of large vacuumizer, vibrator is made otherwise there.

Base with electric and pneumatic output.

There are two outputs made in base the one is intended for electromagnet power feeding, the other is for air aspiration.

At the point where cables are coming out you should place the sockets. Please make sealing inside using Epoxilin.

You should put T-joint on air fitting. Please connect valve for vacuum discharge to the T-joint.

It`s better to use ball valve, if you will find the suitable small one. As my experience with first switch on the device has shown me,

connection of vibrator directly to power net causes too strong vibration and splashing of compound. Vibration controller is needed.

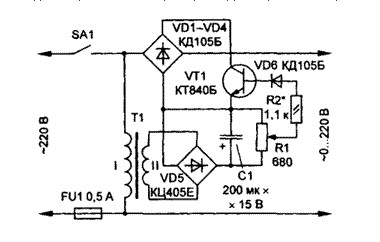

I decided not to cut sinusoide, but to change its amplitude only. The cutted sinusoide doesn`t work very well on induction load.

I implemented the well-known scheme (source: Russian specialized magazine Radio, vol.11, 1999).

In order not to waste time for its searches please find attached the

description.

Scheme of amplitude control of power net and its application in use.

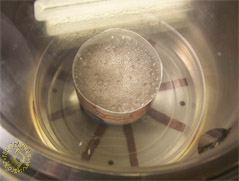

I`d like just to add, that you should put any easy tank on membrane, because while vacuumizing the compound will get almost twice in volume.

Therefore the tank is needed, in order not to flood electromagnet. I implemented the plastic container of salted hering after use :)

Vacuumizing of Investment.

Please notice: right below corner input for manometer is protected by shuttler. And tank is positioned as slightly raised above membrane for air outcoming.