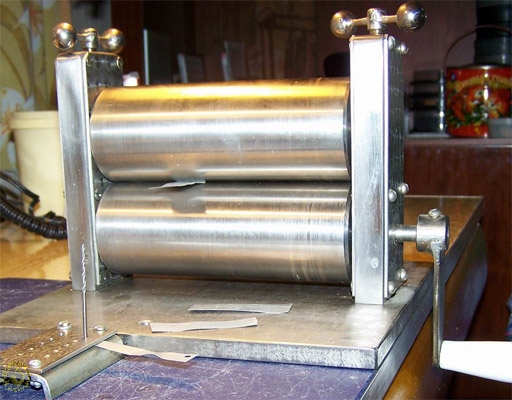

Homemade Manual Rolling Mill

There is almost nothing to describe in this mills. Initially the mills were classified into classes, designed for purposes as follows:

rolling of filigree, for alignment and correction of sheet materials. But due to the fact I didn`t designed fancy shaped streams, these settings were then useful while rolling of materials for sculpting.

I mean burnable plastics Super Sculpey, Fimo and Tsvetik (made in Russia). These solutions are suitable for sculpture clay.

It will be convenient if there were 2-composites compounds of type Epoxy Putty, the proceed surfaces should be cleaned up and covered by plastics.

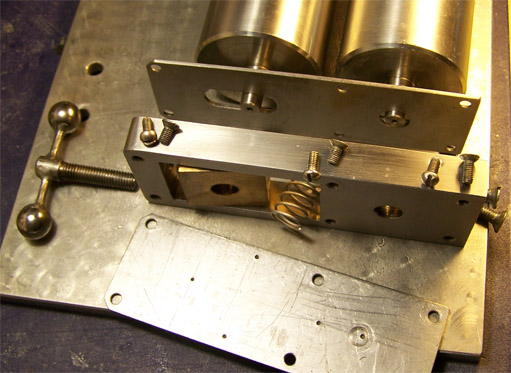

I made different regulation for each side. Because, maybe will make cookies of different thickness :))

But - to be serious – it makes construction easier.

In in-plant-made mills, there is a control option presented by toggle switch. Then, rotation goes through the gear – to both of shoulders.

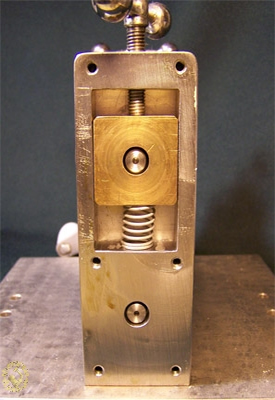

Here, each shoulder should be aligned individually. I have set of calibrated plates for this purpose, it makes selection issue not complicated.

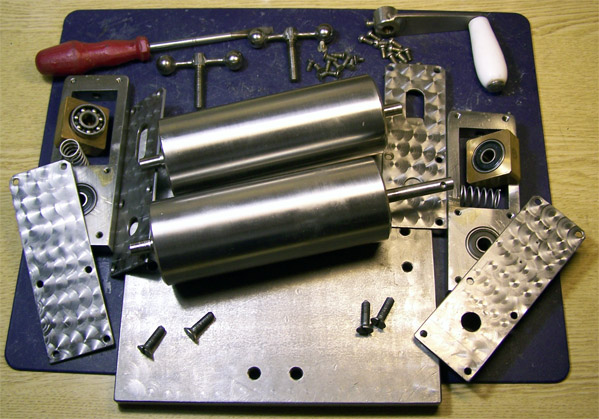

All the rest is shown on picture.

This device has one disadvantage: Handle has to be rotate manually, device will be set on somebody`s edge of tables.

It seems to be a little bit complicated – but it`s ok. Why should our life be so simple? :)

Detailing

All components for manufacturing are shown in the drawings:

Drawing1,

Drawing2,

Drawing3,

Drawing4,

Drawing5.

In addition, you need the following items:

- bearings Ή60029 D = 26 / 9- 2 pieces;

- a spring with a diameter of 15 mm and a length up to 30 mm-2 pcs.

All items and build order in the photo below. How to make the handle and beat

two adjusting screws I leave for your consideration.